Xylene

A volatile liquid hydrocarbon obtained by distilling wood, coal tar, or petroleum, used in fuels and solvents and in chemical synthesis.

Xylene (C8H10) is a colorless, flammable liquid with a sweet odor. Exposure to xylene can irritate the eyes, nose, skin, and throat. Xylene can also cause headaches, dizziness, confusion, loss of muscle coordination, and in high doses, death. Workers may be harmed from exposure to xylene. The level of exposure depends upon the dose, duration, and work being done.

Xylene is used in many industries. It’s used in the petroleum and wood processing industries. Some examples of workers at risk of being exposed to xylene include the following:

- Painters and furniture refinishers who use paint thinners, solvents, lacquers and paint removers

- Biomedical laboratory workers who use it as a solvent to fix tissue specimens and rinse stains

- Workers involved in distillation and purification of xylene

- Workers employed in industries who use xylene as a raw material

- Gas station and automobile garage workers through exposure to petroleum products

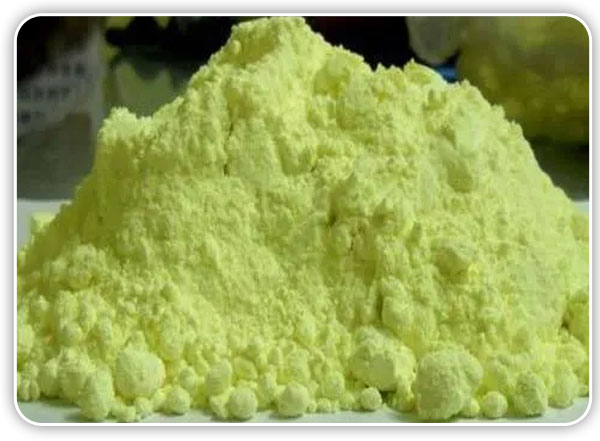

Sulfur

Sulfur is a chemical element that is present in all living tissues. After calcium and phosphorus, it is the third most abundant mineral in the human body. Sulfur is also found in garlic, onions, and broccoli.

Sulfur is applied to the skin for dandruff and an itchy skin infection caused by mites (scabies). It is also applied to the skin for acne and skin redness (rosacea), and taken orally for many other conditions, but there is limited scientific evidence to support these uses.

Symbol: S

Atomic mass: 32.065 u

Atomic number: 16

Electron configuration: [Ne] 3s²3p⁴

Electrons per shell: 2,8,6

Melting point: 112.8 °C

Boiling point: 444.6 °C

How does it work ?

Sulfur is present in all living tissues. It is the third most abundant mineral in the human body. Sulfur seems to have antibacterial effects against the bacteria that cause acne. It also might help promote the loosening and shedding of skin. This is believed to help treat skin conditions such as seborrheic dermatitis or acne.

Possibly Effective for

- Dandruff. Sulfur is an FDA-approved ingredient used in common over-the-counter products to treat dandruff. However, available research on its effectiveness is limited. Some research shows that using a shampoo containing sulfur and/or salicylic acid twice daily for 5 weeks reduces dandruff. Shampoo containing both sulfur and salicylic acid seems to be most effective.

- Itchy skin infection caused by mites (scabies). Applying a jelly containing sulfur to the skin appears to be an effective treatment for scabies in most people. Sulfur treatments are usually applied overnight for 3 to 6 nights. But this treatment is not pleasant due to the smell. Also, there are better and cheaper treatments available, including the drugs ivermectin and permethrin.

Polypropylene

Polypropylene, also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar.

Melting point: 160 °C

Formula: (C3H6)n

IUPAC ID: poly(propene)

Classification: Polymer

Density: 0.855 g/cm3, amorphous; 0.946 g/cm3, crystalline

Polypropylene Plastic

Polypropylene (PP) is one of the most commonly used thermoplastics in the world. Polypropylene uses range from plastic packaging, plastic parts for machinery and equipment and even fibres and textiles. It is a rigid, semi-crystalline thermoplastic that was first polymerised in 1951 and is used widely today in a range of domestic and industrial applications. Today, global demand for polypropylene is estimated at around 45 metric tons and this figure continues to rise exponentially.

Polypropylene has a slippery, tactile surface, making it ideal for

- plastic furniture

- low friction applications, such as gears in machinery and vehicles.

- It is highly resistant to chemical corrosion, making it an excellent choice for packaging for

- cleaning products

- bleaches and first-aid products

It offers excellent fatigue resistance and elasticity, securing it a well-deserved reputation for toughness and durability. Polypropylene has high insulation properties too, making it safe to use for plastic casing in electrical goods and cables. In its fiber form, polypropylene uses are not limited to not only useful for tote bags but also encompass a much wider range of other products, including ropes, twine, tape, carpets, upholstery, clothing and camping equipment. Its waterproof properties make it especially effective for the marine sector. In the automotive industry, polypropylene is also used widely, for example in for battery casings, trays and drink holders, bumpers, interior details, instrumental panels and door trims.

Finally, the medical world appreciates the waterproof properties of polypropylene too, as well as its flexible strength, resistance to mould, bacteria and chemical corrosion. It cleans well as it can stand up to steam sterilisation methods. Some medical applications include,

1. syringes

2. medical vials

3. Petri dishes

4. pill containers

5. specimen bottles

Material properties and types of polypropylene

This versatile thermoplastic and polymer are popular due to its highly flexible properties, lighter density and ability to adapt to a range of fabrication techniques. The different variations in polypropylene have led the material to be known as the ‘steel’ of the plastic industry, as it can be used and manipulated a number of ways.

There are two main types of polypropylene thermoplastics:

1. homopolymers

2. copolymers

Homopolymers contain only propylene monomers in semi-crystalline form Main uses include textiles, packaging, pipes, medical components and electrical applications.

Copolymers are divided into random copolymers and block copolymers, produced by polymerising propene and ethene together. Copolymers contain higher amounts of ethylene, which result in an increase in desirable properties within the polypropylene. They are softer than homopolymers but have better impact strength.

Polypropylene can function as both a plastic and fibre type of thermoplastic. This allows for a vastly increased range of uses. It can be used as a fibre, such as in the manufacture of promotional tote bags and ‘bag for life’ shopping carriers. It is soft, malleable and has a relatively low melting point, making it very easy to be used in the injection moulding process, where it is supplied in pellets. It flows well too, due to its low melt viscosity.

Advantages to Polypropylene

Due to the fact that polypropylene adapts well to the injection moulding process, it can be used to make incredibly thin layers of plastic. It is very suited to applications such as

- hinges on medication pots,

- lids on shampoo bottles

- and other containers that will be bent and manipulated a lot and mustn’t break.

Polypropylene can even withstand twisting motions of up to 360 degrees without snapping and is very hard to snap as a result. It is relatively low cost and straightforward to produce and readily available in multiple countries and communities. High chemical and fatigue resistance add to its durability and versatility as a packaging material and option for hinges and bottle tops attached to the main bottle by a thin layer of plastic. It can offer great versatility in colour, as it can be produced as an opaque or transparent thermoplastic and used when some transfer of light is desired. Its lighter density allows it to be used in applications where weight saving has to be a key consideration. Polypropylene is waterproof and extremely resistant to moisture absorption, which adds to its packaging benefits and flexibility as a packaging material. Its semi-crystalline nature offers high flexural strength too, making it resilient to general wear and tear and ideal for items that must undergo higher levels of physical stress. It is also resilient against mildew, mould, rot and bacteria.

APP

Atactic polypropylene, referred to as APP, is an amorphous and rubbery thermoplastic material. It is used primarily in bitumen modification and adhesives. APP is available from on-purpose production (APAO), as a byproduct of polypropylene production (APP) and as a produced-to-specification synthetic compound.

Atactic polymers are characterised by their tacky texture, amorphous behavior and low molecular weights. Where present they act as a plasticiser by reducing the overall crystallinity of the PP. From a commercial viewpoint, isotactic PP is the most important form of the polymer.

Atactic polypropylene, referred to as APP, is an amorphous and rubbery thermoplastic material. It is used primarily in bitumen modification and adhesives. APP is available from on-purpose production (APAO), as a byproduct of polypropylene production (APP) and as a produced-to-specification synthetic compound.

Copyright by @Petro Seal Enterprises. All Rights Reserved